White Paper on Quality Control of the Full Supply Chain of Album Design and Production Companies | Guide to Avoiding Pits

Have you ever had this kind of headache? A corporate album that spent a lot of money to make, but when you get it, you find that the color is dull, the paper is crisp, the binding is askew, and even there are typos? To make matters worse, suppliers shirk each other and can't find anyone to take responsibility? Don't worry, today's white paper is to help you avoid these pitfalls, find a truly reliable album design and production company, and make your corporate image win at the starting line on paper!

A giclee isn't just a few sheets of paper, it's the silent face of your brand.

A high-quality picture album that instantly boosts customers' trust and professionalism in your company. However, there is a long supply chain between turning "good ideas" into "high-quality objects" in the hands of customers. Many companies only value design and price, but ignore the complex production process and quality control nodes behind them. This is where the hidden danger lies.

Pain point: the "album pit" we stepped on in those years

"The design pictures are picturesque, but the real objects are ugly": the careful design is dazzling on the screen, but when printed, the color is dim and distorted, and the material feels cheap, which instantly lowers the brand grade.

"Procrastination becomes a habit, and the delivery date is always changing": When you agree to deliver goods in two weeks, there are always various reasons to delay, disrupting your marketing plan, and you are as anxious as ants on a hot pot.

"Mistakes fly all over the sky, and the ball is kicked after sales": wrong text, blurred pictures, and skewed binding. After discovering the problem, the design company pushes the printing factory, and the printing factory blames the design documents. In the end, the bitter fruit can only be swallowed by itself.

"The cost is a mystery, and the price increase is unreasonable": the quotation seems reasonable, but all kinds of "necessary" additional expenses appear in the production process, and the budget is seriously overspent.

Why do problems occur frequently? Disconnected supply chain is the culprit!

Under the traditional mode, design companies, printing plants and post-processing plants are often separated. The design doesn't understand the limitations of the printing process. The printing factory only works according to the documents without delving into the design intention. The post-processing is only responsible for its own process. Information transmission is like "drumming and passing flowers". If any link falls off the chain, the final product will have problems, and quality control will be impossible to talk about.

The way to break the situation: in-depth collaboration of the entire link, allowing quality control to run through "from idea to fingertips"

A truly excellent album design and production company is not just as simple as a design scheme. Its core competence lies in the deep integration and precise quality control of the entire supply chain, ensuring that your album is in a controllable and traceable high standard from conception to delivery. This requires several key supports:

Design: from "armchair strategist" to "taking root"

Designers who understand craft: Designers should not only understand aesthetics, but also be proficient in printing technology, material characteristics, and post-process (such as bronzing, UV, bumping, etc.). Know how to avoid printing pitfalls at the design stage, and choose the solution that best suits the rendering effect and has a controllable cost.

"Productivity" pre-review: At the beginning of the completion of the design draft, internal prepress experts will intervene in the review to check the document resolution, color mode (CMYK), bleeding position, feasibility of special processes, etc., so as to nip problems in the bud. Instead of waiting for something to go wrong before modifying it, it is often costly.

Physical proofing verification: For important projects or complex processes, insist on making high-precision physical proofing before mass production. Designers, customers, and production leaders jointly check the color, material, and process effects, and sign for confirmation before putting into production to avoid batch errors.

Prepress: Clearing the way for perfect output

Professional document processing center: equipped with professional prepress personnel and technical equipment (such as high-end color calibrator and imposition software), standardized processing, accurate color management (ICC Profile) and standardized imposition of the final confirmed design documents to ensure that the documents are delivered to the printing press with "zero errors".

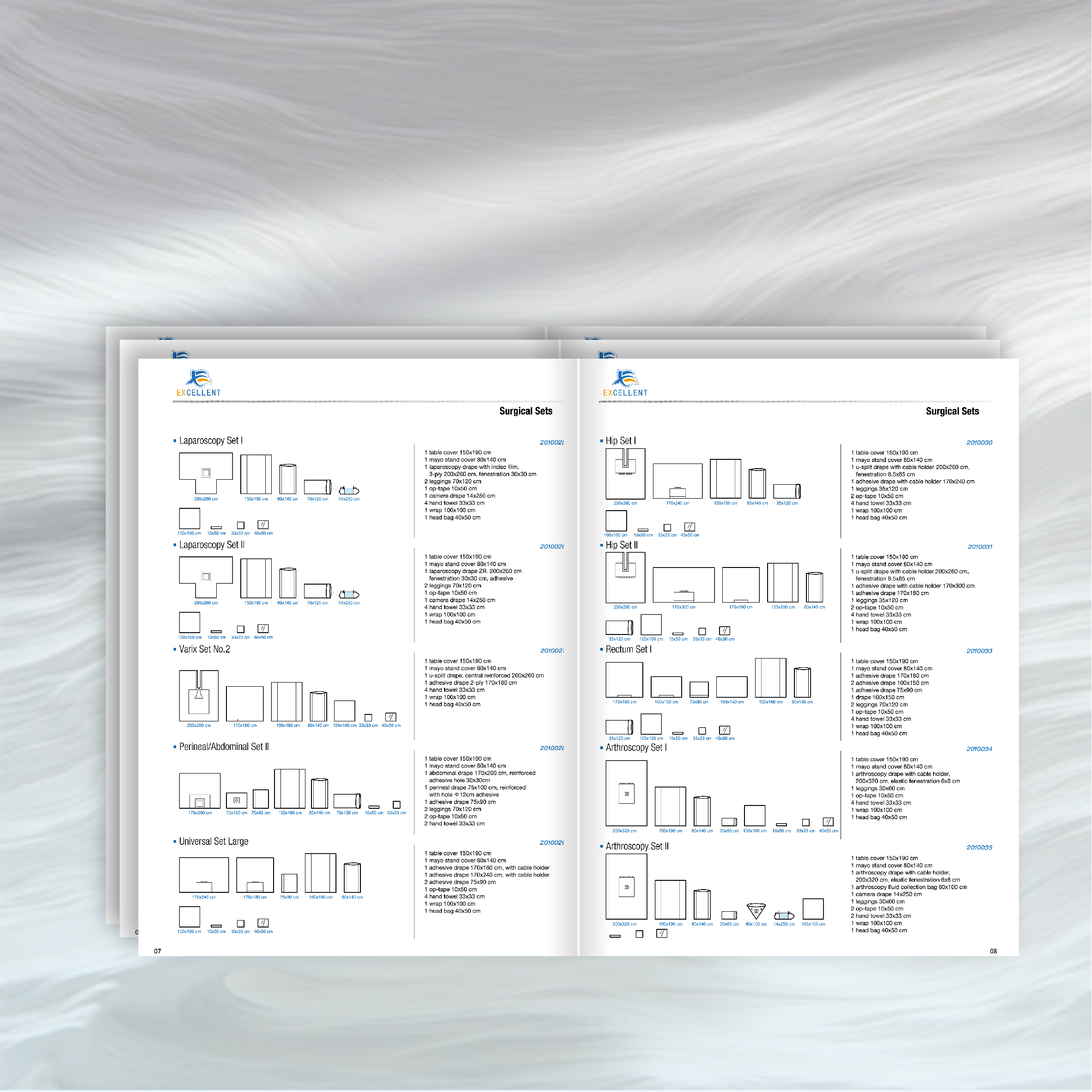

Material library and effect simulation: Establish a rich physical library of paper, special materials and binding materials. In the design stage, customers can touch and feel intuitively, and combine software to simulate the printing effects on different materials, thus reducing the gap between real objects and imagination.

Supplier transparency: inform customers of alternative brands, models, characteristics and price differences of main materials (such as core paper) in advance, and make joint decisions to avoid passivity caused by material shortages or cost surges in the later period.

Printing and processing: the process is visible and the quality is controlled

Deep binding of core factories: Instead of finding any printing factory to cooperate with, we establish long-term strategic cooperation with core printing factories with reputation in color management, equipment accuracy and stability. Even quality control personnel are stationed in the factory.

First article sample signing system: After the printing press is started and debugged stably, the first complete sample (first article) produced must be signed by the quality control or customer representative in the factory to confirm the key indicators such as color and registration before mass production can be carried out.

Production inspection and key point control: During the production process, high-frequency inspections and random inspections are conducted on key links (such as large-area spot color printing, fine registration pages, and special materials on the machine) to promptly discover and correct minor deviations.

Specialization of post-processing: For laminating, hot stamping, UV, binding (glue binding, saddle stud, hardcover) and other processes, we choose professional processing factories in the field to cooperate, and also implement strict process standards and first sample confirmation process. In particular, experienced masters and strict control are needed to make the shell surface and paste the text of hardcover books.

Packaging and Delivery: The Last Guard

100% full inspection of finished products: Before packaging, manual full inspection of each album (or manual key review of high-precision machine vision sampling inspection) is carried out. The inspection contents include but are not limited to: whether there are dirty spots, scratches and corners on the front cover, back cover and inner pages; Whether the binding is firm and straight; Whether the page numbering order is correct; Whether the special process effect meets the standard.

Scientific protective packaging: According to the size, quantity and transportation distance of the album, appropriate protective packaging (such as rigid carton, moisture-proof film, corner protector, bubble bag filling, etc.) is adopted to ensure that it is still as good as new when it arrives in the hands of customers after long-distance transportation. Put an end to simple bundling or crude cartons to deal with things.

Traceability system: Establish the whole process record (paper or electronic) from design draft version, production batch number to final delivery to customer. Once there is any doubt, it can be quickly traced back to the source of the problem and the responsibility link.

Customer Stories: Visible Quality Commitment

A well-known technology company launched its annual flagship product, and urgently needed a batch of high-end hardcover albums for global press conferences and VIP customer gifts. They found an album design and production company with full supply chain management and control capabilities. The cooperation process fully reflects the value of in-depth quality control:

Design stage: The designer proposed a scheme of using metallic special paper combined with local UV and blackening processes, and at the same time communicated closely with the prepress and production teams to ensure that the process was feasible and the effect was optimal. Physical proofs containing all processes were made for customer confirmation.

Production stage: Select top brand metal paper, and monitor the whole process of quality control in the factory. When signing the first sample, it is found that the blackening effect is slightly insufficient under specific light, so the hot stamping pressure and temperature are immediately adjusted until the standard is perfectly reached before mass production. In the hardcover link, the flatness of the book case pasting and the firmness of the text pasting are randomly checked one by one.

Delivery stage: Each album is independently laminated and put into a custom-made hard heaven and earth cover box, and then packed for transportation. In the end, thousands of albums were presented at the global press conference on time and perfectly, and their excellent texture and craftsmanship details were highly praised by customers and became a powerful tool to convey the brand's high-end image.

Choosing a partner means choosing peace of mind

A successful picture album is the common crystallization of strategy, creativity, craftsmanship and ultimate quality control. In the era of information overload, a picture album with real touch, exquisite details and brand spirit is still the "hard currency" to impress customers and build trust.

The next time you need to look for a giclee design and production company, don't be attracted only by gorgeous design drafts or attractive low prices. Ask in depth:

Do your designers really understand the boundaries between print and craft?

How do you ensure that my design drawings don't "change face" in the printing process?

Who is keeping an eye on me during the production process? Who is responsible if something goes wrong?

Can each of the picture albums I finally get stand up to the criticism of me and my clients?

Truly trustworthy Album design and production company, the answer will clearly point to the control of the entire supply chain and the quality control awareness integrated into the blood. They regard each album as an extension of brand reputation, and touch the nerve endings of quality control to every link from inspiration to finished product. Choosing such a partner means that you choose not only a service, but also a commitment to quality and joint protection of brand image. Let every picture album from their hands become a silent but powerful spokesperson for your brand.