Distributed printing of product brochure design and production: QC standards for global multi-point synchronous production

Have you had this experience? Carefully designed product brochures, printed in different cities and factories, with different shades of color and different paper feel? This is simply the "invisible killer" of brand image! Today, let's talk about how to use the sharp tool of distributed printing to solve this pain point, so that your good design can be perfectly presented in any corner of the world!

1. Why may your good design be "ruined" in printing?

Think about it, you have made great efforts to find a professional team to complete the design and production of product brochures, from planning, copywriting to visual presentation, and strive for perfection. However, the problem arises when the design draft is delivered for printing, especially when it needs to be printed simultaneously in multiple regions (such as headquarters, different regional branches, and overseas markets :

"Shanghai printing is deep, Shenzhen printing is light"-color consistency is out of control: different printing factories have different equipment, inks and master experiences, resulting in visible differences in the color of the final product, and the brand standard color becomes a "chameleon".

"This batch is thick, that batch is thin"-the material feel is erratic: the "high-end texture special paper" promised to customers may become ordinary paper due to paper inventory or understanding deviation when it is implemented in different printing factories, and the brand tonality is greatly reduced.

"The edges of text are blurred, and the accuracy of pictures is not enough"-the quality of details is uneven: small losses in file transfer, differences in RIP (raster image processing) of different devices, and the fine-tuning habits of printing masters can all make the well-designed details become blurred.

"The goods from the headquarters have arrived, but the goods from the branch are still floating on the sea"-timeliness is difficult to guarantee: centralized printing in one place and then global distribution, the logistics cost is high and time-consuming, and it is beyond the reach of urgent needs or sudden modifications.

These pain points are essentially due to the traditional centralized printing or random decentralized factory search model, which lacks a set of strong, enforceable, and monitorable global unified quality control standards (QC standards). When your brochure needs to bloom in many places around the world, the "last mile" of quality becomes the biggest risk.

2. Distributed printing: innovation on the manufacturing side makes global printing like "one factory"

Distributed printing is not simply about sending documents to printing factories all over the globe and it's done. It is a systematic innovation, the core of which lies in digital, standardized and intelligent process reengineering, so that multiple geographically scattered printing points can operate like a highly collaborative "super factory", and the output is highly consistent and in line with the design. Original product brochure. Behind this is a new set of global multi-point synchronous production QC standard system supporting:

1. The core pillar of QC standards: the whole digital chain from "source" to "finished product"

"Design as a standard" digital asset library: This is not just about storing design files (e.g. PDF, AI). The key lies in translating the design intent into machine-readable, executable printing parameters. This includes:

Digital passport of brand colors: precise CMYK values, spot color PANTONE numbers and their corresponding Lab values (closer to the color space perceived by the human eye), even containing a description of the desired effect on different paper types and acceptable minor range of deviations (ΔE values).

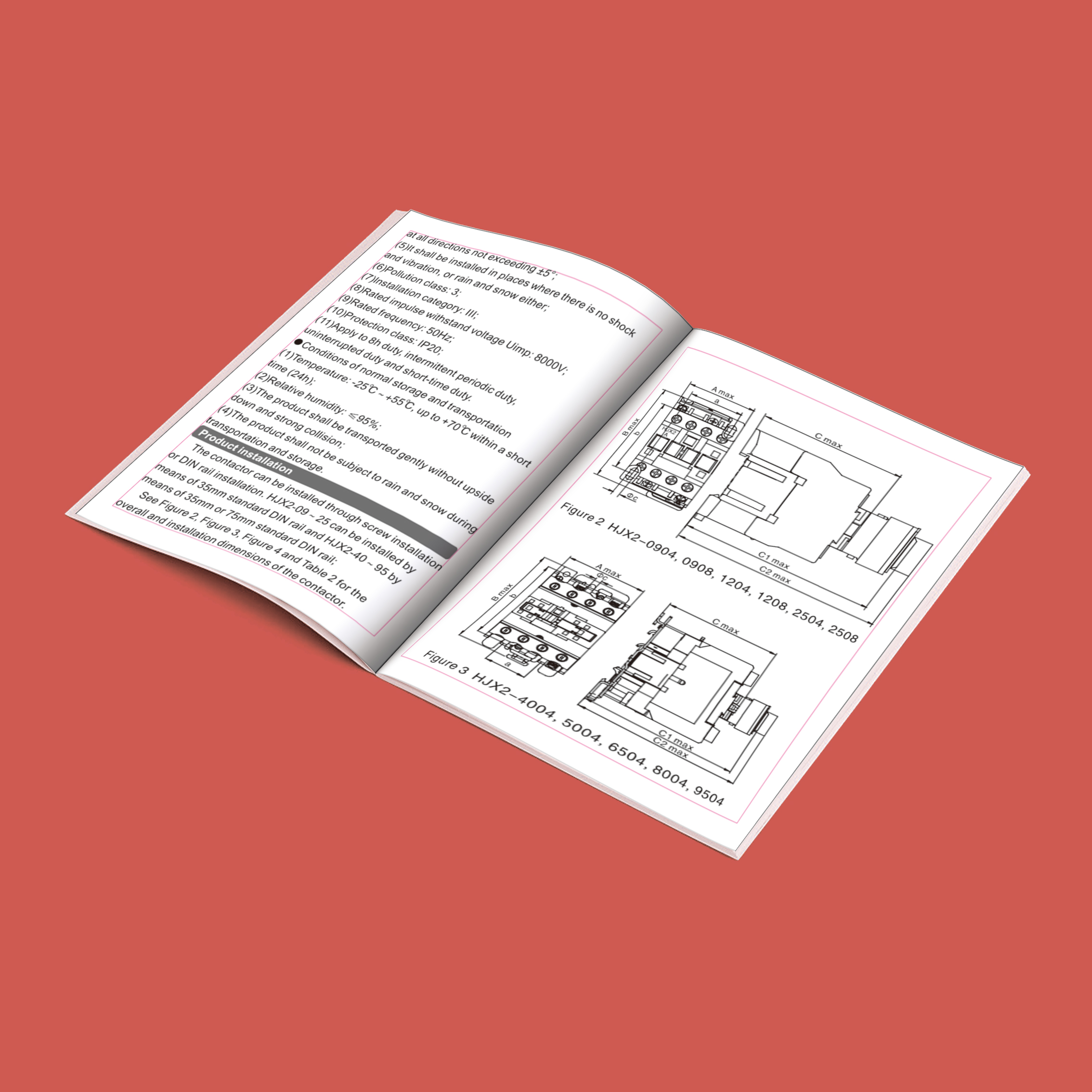

"Fingerprint" certification of the material: specify the brand, model, weight, surface treatment (such as matte powder, gloss copper, tactile film) of the paper, and provide standard proofs or accurate physical characteristics description (whiteness, smoothness, etc.).

"Operation manual" of the process: version number of bronzing/silver, position accuracy, pressure parameters; Area documents and varnish thickness requirements for UV local glazing; Knife plate documents for die cuts, bleed requirements, etc.

The "ruler" of graphic accuracy: the minimum font size of key text, the fineness of lines, the resolution and sharpening standard of pictures. These parameters are integrated into a central cloud platform, and global cooperative printing factories can access them in real time according to their permissions, ensuring consistent understanding from the source.

Cloud pre-inspection and intelligent distribution "hub": After the design draft is uploaded, it is not sent directly, but conducts in-depth pre-inspection through the intelligent system:

Automatic error correction: Checks font embeddings, picture resolutions, bleed settings, color modes, etc. for compliance with preset Global Printing Basics specifications.

"Simulated printing": According to the specific equipment model and common consumables of the target printing factory, perform color space conversion simulation, predict the final effect, and automatically generate printing preset files (such as CTP version curve and ICC color configuration file) optimized for the equipment.

Accurate routing of tasks: The system intelligently assigns printing tasks according to customer needs (delivery place, quantity, delivery date), the real-time production capacity of the printing factory, expertise (such as whether it is good at thick cardboard packaging or tissue paper manuals), and geographical location, and automatically pushes matching, Printing work orders containing all necessary QC parameters. "One design, global adaptation".

2. Implementation of QC standards: "same frequency resonance" of global printing factories

"Visible" global collaborative quality control center: a unified digital management platform is the core. On this platform:

Transparency of task status: Customers, brands, and printing factories can see in real time which link each order is in (document reception, prepress preparation, machine printing, post-processing, quality inspection, delivery).

Real-time data aggregation: Key production data of each printing factory (such as real-time density curve of printing machine, Lab value fed back by color measuring instrument, ambient temperature and humidity) are automatically uploaded to the platform and compared with preset standards.

Automatic abnormality warning: Once it is detected that the real-time data exceeds the preset tolerance (such as the color ΔE of a certain batch > 2.0), the system will immediately send an alarm to the person in charge of the printing factory and the QC personnel of the brand, requesting suspension or adjustment.

Knowledge sharing center: Accumulate best practice parameters of different materials and processes in different environments (such as high humidity areas) to form a reusable experience library to guide global production.

"Tangible" physical anchor points: standard proofs and intelligent detection:

The authority of "gold standard": the world's only standard physical proofs jointly confirmed and sealed by the brand, designer and core printing factory are very important. It is not only a visual reference, but also a benchmark for physical touch. All distributed printing plants must measure the standard sample with a certified instrument (such as spectrophotometer) before starting the machine, and calibrate our factory equipment with this to ensure the same starting line.

"Fierce eyes and golden eyes" online detection: the printing press is no longer "blind printing". High-precision online vision inspection system (CCD camera) scans printed sheets in real time:

Color Guard: Continuously measure the color value of key color blocks, compare it with the standard, and immediately feed back the offset to the printing press to automatically fine-tune the ink key.

Defect Hunter: Automatically identifies defects such as scratches, ink skin, inaccurate overprinting, dirty spots, etc., and marks or triggers alarms.

Content proofreader: Check whether the key words, barcodes, and Logo positions are 100% accurate. This is equivalent to installing countless tireless quality inspectors in high-speed printing.

"Closed-loop" global linkage and feedback:

"Cloud" collaboration of first item confirmation: the high-definition pictures and key measurement data of the first batch of proofs (first item) of each printing factory are uploaded to the platform, and the brand/designer remotely review and confirm online, which greatly shortens the traditional sample sending time.

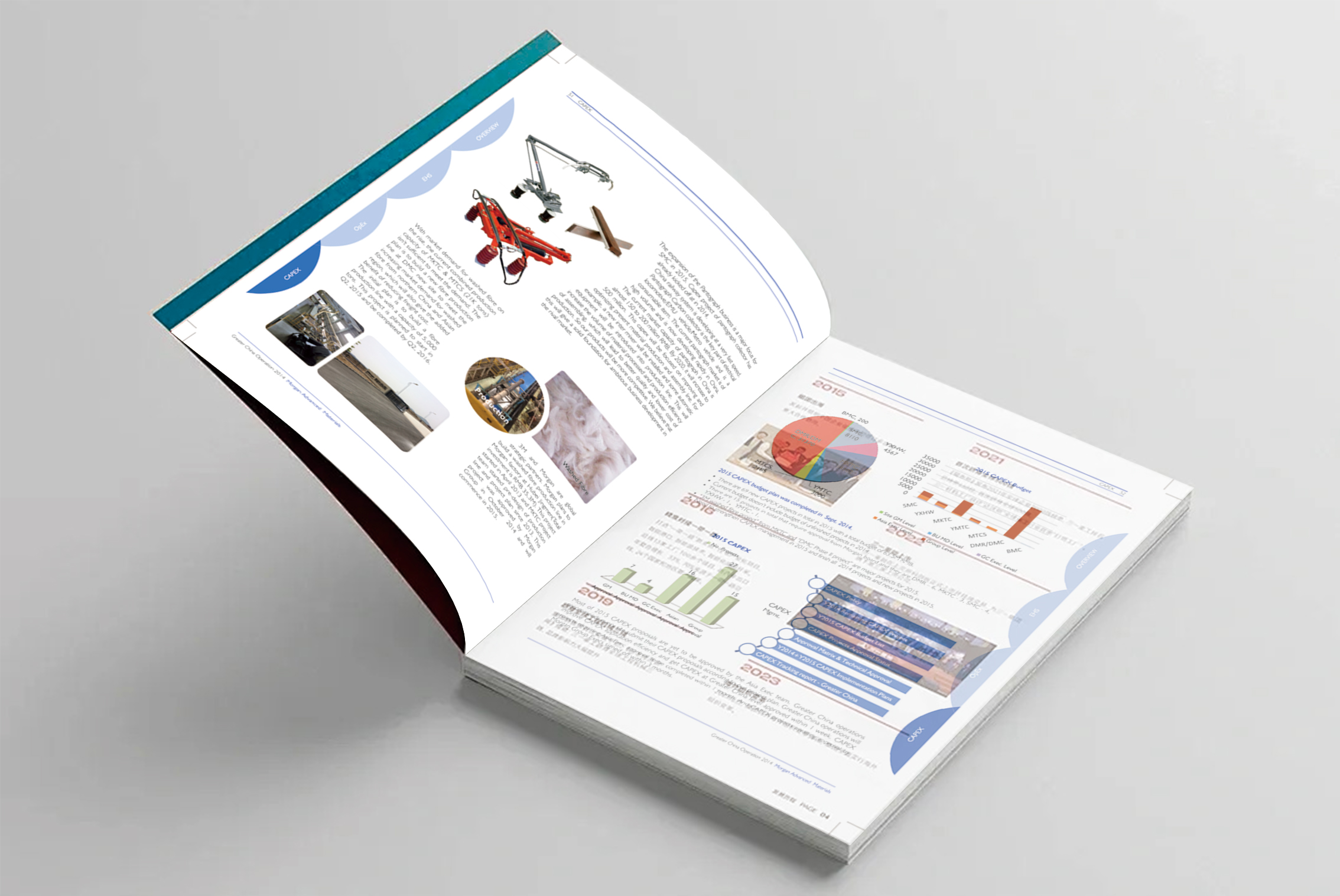

Continuous optimization driven by big data: The platform collects production data, quality inspection results, and exception handling records of factories around the world. By analyzing these data, we can find out the key factors that affect quality (such as the performance law of a certain type of paper under specific temperature and humidity), constantly optimize the preset standards and process parameters, and make QC standards more and more intelligent and accurate.

"Survival of the fittest" of printing factory capabilities: Platform data objectively records the stability and compliance rate of each cooperative printing factory, providing a basis for subsequent task allocation and supply chain optimization, and ensuring that the entire distributed network is at a high level.

3. The "true fragrance" law of distributed printing QC standards: a win-win situation for brands and printing partners

This set of strict global QC standards brings far more value than "printing the same":

To the brand side (you):

Brand image is rock-solid: Whether customers get brochures in Tokyo, Paris or New York, they feel completely consistent brand professionalism and high-quality experience, and their trust is doubled.

Fast decision-making and fierce listing: there is no need to wait for transoceanic transportation, printing at multiple points around the world, and the response speed of new product releases and promotional activities is increased several times, so as to seize market opportunities.

Better cost and lower risk: save huge logistics costs and time costs; Decentralized production reduces the risk of supply chain disruption caused by single factory shutdown and natural disasters; Unified bargaining enhances the right to speak in the purchase of bulk consumables such as paper.

Agile Response to Change: Found an error in manual information or need to be updated? Through one-click push of new documents and revised instructions on the platform, global printing factories update simultaneously, bid farewell to recall nightmares and version confusion.

To printing partners (us):

Win the trust of high-end customers: Printing factories that can stably implement strict global standards are the preferred partners for international brands and high-end product brochure design and production projects, and enhance their industry status.

More efficient and smoother production: Clear standards and intelligent tools (pre-inspection, online inspection) significantly reduce communication costs, rework waste and production stops, and significantly increase equipment utilization and per capita output.

Continuous improvement of technical capabilities: integration into the world's advanced digital production network, exposure to cutting-edge technologies and process standards, forcing its own management and technological upgrades.

Globalization of business opportunities: Become a reliable node in the global distributed printing network, and have the opportunity to undertake more international business from platform distribution.

Case highlight: A world-leading consumer electronics brand, its high-end product line brochure requirements are strict (special metallic color, complex process, global simultaneous sale). The adoption of distributed printing and the above-mentioned QC standards not only ensures that the brochures printed from Silicon Valley to Singapore to Munich are accurate, but also shortens the overall project cycle by 40%, successfully supporting its global lightning release strategy.

4. Embrace the future: unbounded quality, reaching the world

Global multi-point simultaneous printing is no longer a scene in science fiction. When a set of rigorous, intelligent and landable QC standards run through the whole process of product brochure design and production, especially the key link of printing and manufacturing, distance and geography are no longer obstacles to quality.

This is not only an upgrade of technology, but also a leap of service concept. It means that service providers who focus on the design and production of product brochures are no longer just delivering a design document or completing local printing, but must have the ability to integrate global high-quality manufacturing resources, establish and implement strict quality control systems, and become customers' trustworthy "global quality guardians".

Choosing a partner who is well versed in distributed printing QC means choosing to keep your brand image at its peak in any corner of the world. Let good design not be "dragged back" by printing; Let good products shine in the world because of the perfect brochure! We not only understandProduct brochure design and productionBeauty, better knowing how to make this beauty consistent across mountains and seas.